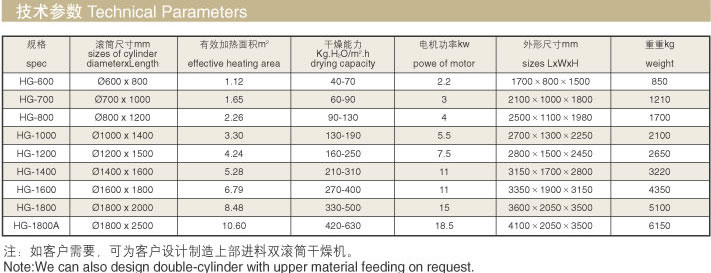

| REMARK: |

Overview:

The drum dryer is a heated the conduction rotating continuous drying equipment. Rotation of the drum through the bottom trough, adhesion with a certain thickness of the material film, heat is piped to the cylinder wall, conduction to the drum outer wall, and then transfer to the material film, so that the moisture in the material film to be evaporation, drying, so that the moisture content of materials to get dry. Dry good material to be installed in the drum surface scraper shovel away from the drum, in the scraper bottom of the unsuccessful conveyor, screw conveyor and then dry material concentration of packaging.

Features:

◆ high thermal efficiency. Drum dryer to heat conduction mechanism is heat conduction, heat transfer direction is consistent with the entire operating cycle cover heat dissipation and thermal radiation losses, the remaining heat all term tube feeding moisture evaporation, the thermal efficiency of up to 70% -80% .

◆ operating flexibility, wide applicability. Adjustable drum dryers the drying factor. The feed concentration, the film thickness of coating material, the heating medium temperature, drum rotation speed, can change the drying efficiency of the drum dryer, and many other factors not involved in each other. Bring great convenience to drum drying operation, so that it can adapt to a variety of materials, drying and production requirements.

◆ the short drying time. Drying cycle of the materials generally only 10-300 seconds, the most suitable for heat-sensitive materials. If the drum dryer is set in a vacuum high regard, and can be run under reduced pressure.

Rate ◆ dried. Applied on the cylinder wall material film is very thin, generally in the 0.3-1.5mm, and heat transfer, mass transfer in the same direction, the surface of the material film can maintain 20-70kg.H2O/m2.h the evaporation intensity.

|